- Homepage

- Vehicle Search Engine Registration

- JCD Info▼

- Cost and Services▼

- JCD MERCH

- Sold and Exported JDM Vehicles▼

- Japanese Domestic Market▼

- Kei Vehicles▼

- Car News▼

- Japan Car News

- Why all the buzz about the Nissan Silvia S16?

- 8 Vehicle Relocation Tips To Make Your Life Easier

- Aston Martin is Huge in Japan

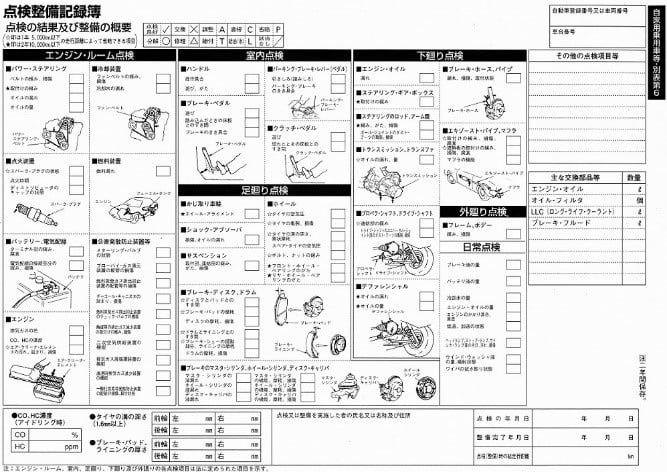

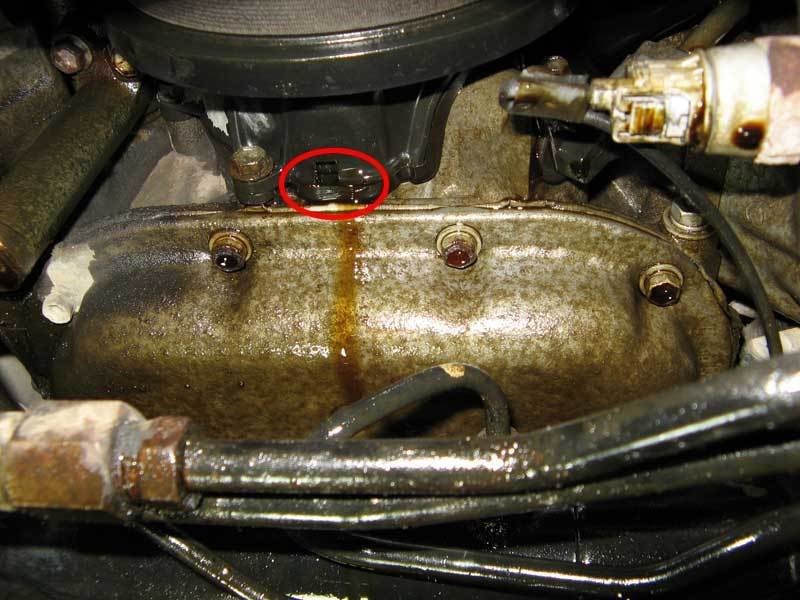

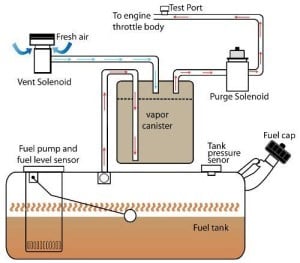

- Shaken and Self Inspection Part 1B

- The 2018 Toyota Century — Japan’s answer to Rolls-Royce

- The Honda NSX returns to Spa 24

- The insane McLaren 600LT meets crazy JDM models from the 90s

- Affordable used Japanese campers

- BMW Unveils The X2 M35i

- 1962 Ferrari 250 GTO – The most expensive car ever?

- Premium JDM Classics Part 2

- Honda Won Four 2018 ‘Best Cars for the Money’ Awards

- Premium JDM Classics Part 1

- Drifting on the Cheap: PVC Drift!

- Toyota Rotary Engine Vehicle Displayed at CES 2018

- Self-healing electric Lamborghini supercar

- Japanese Food Trucks

- One-off BMW M3 30 Years American Edition

- Auto Test: The World’s Safest Motorsport

- 1959 Ferrari California Spyder LWB

- Air-cooled Porsche 911 perfection

- Toyota Announces Gazoo Racing Company

- Shaken and Self Inspection

- The First FIA Intercontinental Drifting Cup!

- 2006 Mitsubishi Lancer Evo IX sells for $138,000

- Subaru WRX STI sets new record

- Japanese Engine Displacement

- 3,000 hp Nissan GT-R

- Porsche unveils the fastest, most expensive Porsche 911 ever

- Extreme Camber in Japanese Cars

- Incredible Group B Rally auction featuring Lancia Delta S4 Stradale

- Shipping Destinations▼

- Info and Terms▼

- Frequently Asked Questions

- How To Read Auction Sheets

- Vehicle Search Engine

- JCD BLOG

- Contact Us